Research on Cryogenic Heat Transfer

Release date: 2025-05-16

Visits: 401

Source: 山东高等技术研究院

Research on Cryogenic Heat Transfer

At milli-Kelvin temperatures, the unique physical properties of helium result in phenomena and patterns of heat transfer and flow that differ from those at normal temperature ranges. A deeper understanding of its mechanism will provide more possibilities for cryogenic heat transfer and the corresponding component design. To address these challenges, the thermal science team has undertaken the following research:

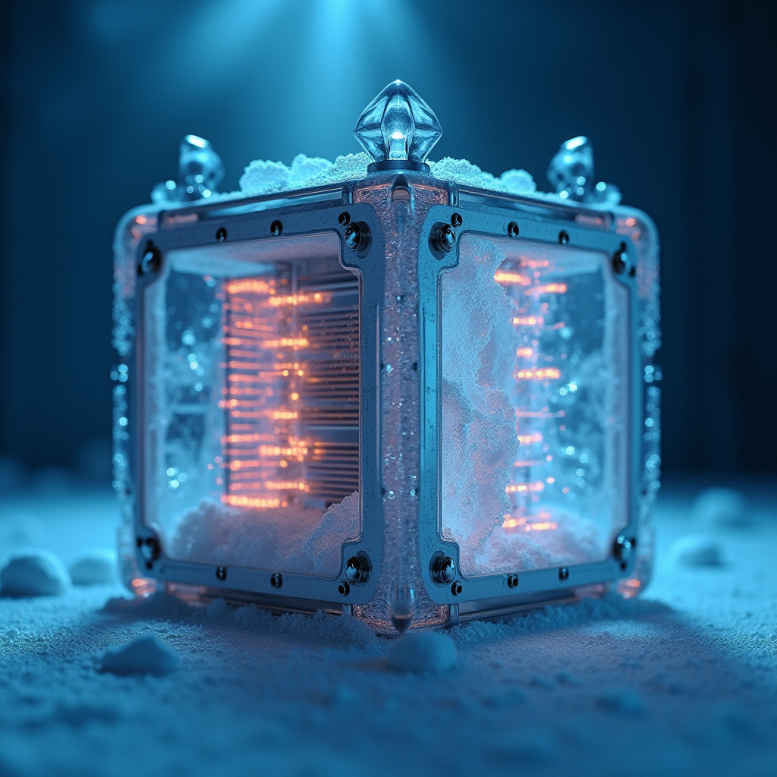

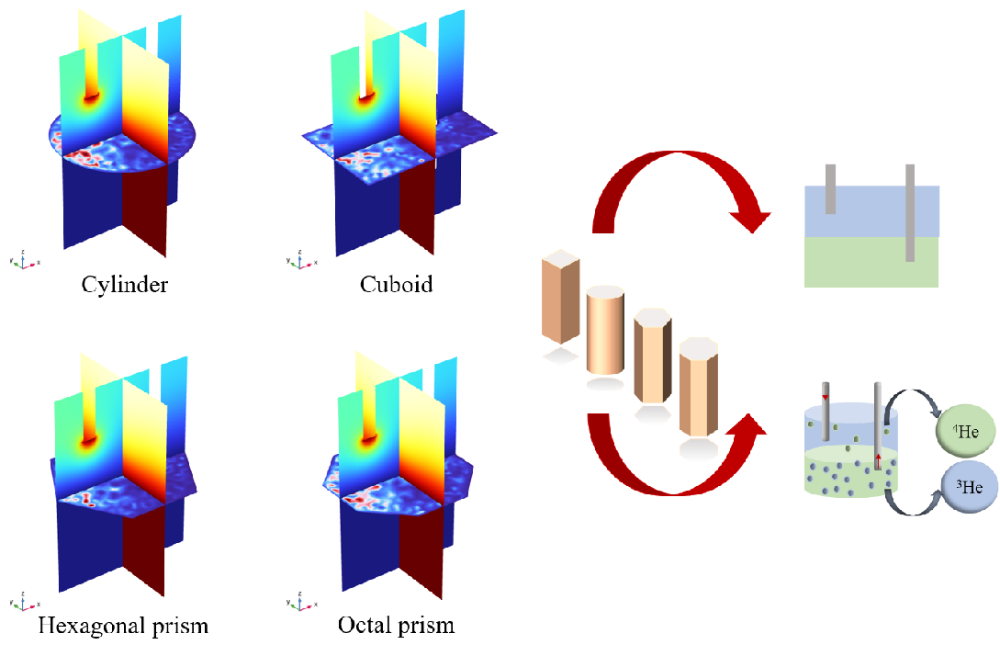

(1) Study on the phase separation characteristics and heat transfer mechanism of 3He - 4He mixture under the milli-Kelvin temperature range. Based on the modified two-fluid model and seepage theory, an energy model combining heat and mass transfer and a concentration diffusion model were introduced. By controlling the seepage rate and limiting the solubility of the mixture, a coupling model of seepage and heat transfer for the 3He - 4He mixture was established. The relationships between osmotic pressure and cool-ing temperature, power and heat load were clarified. Sensitivity analysis of the structural parameters of the mixing chamber reveals the permeation and refrigeration mechanism by the entropy variations in the phase interface of the 3He - 4He mixture under extremely low temperature.

(2) Research on the cryogenic interfacial thermal resistance. Under extremely low temperatures, significant interfacial thermal resistance between the fluid and solid exists. Based on the acoustic mismatch model, and considering the mode of particle vibration and low-frequency vibration of the skeleton, thermal resistance calculation models were established for three types of liquid helium and solid wall interfaces. The influences of the wall material, structural parameters, and flow parameters on the interface thermal resistance were further analyzed, which provides a theoretical basis for the study of enhanced heat transfer at extremely low temperature.

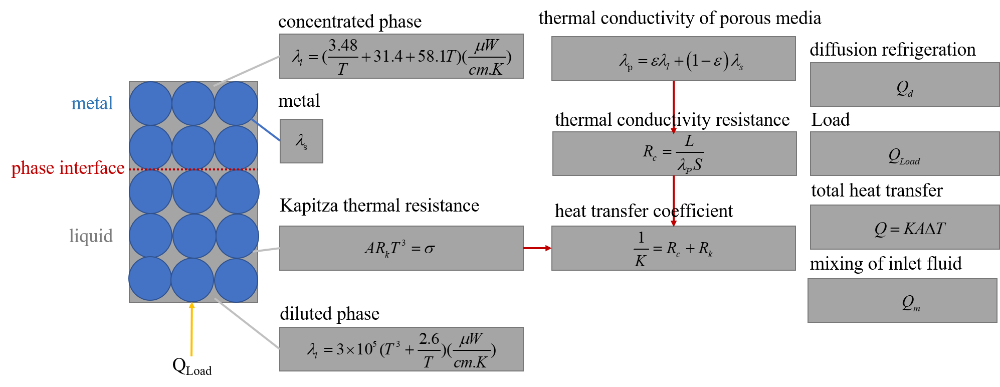

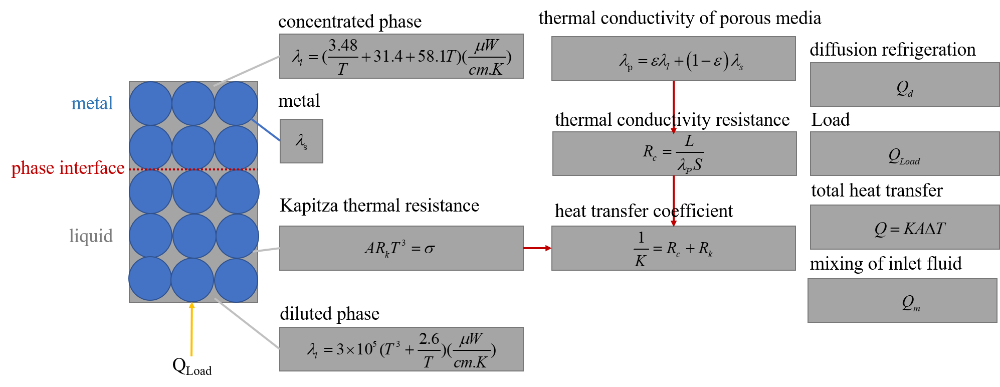

(3) Cryogenic heat transfer characteristics of the porous media. Metal sintered structures are commonly used in milli-Kelvin level temperature heat transfer processes between the liquid 3He and 3He - 4He mixtures, directly affecting refrigeration temperature and cooling capacity. Considering the interface thermal resistance, physical properties of the working fluid, and viscous heat, a numerical model for the heat transfer of cryogenic sintered structures was established based on the non-thermal equilibrium model and the free flow-porous media seepage coupling model. The influences of porosity, sintered particle size, liquid gap structure and volume, thermal properties, and viscous heat on the cryogenic heat transfer and flow were revealed.

(1) Study on the phase separation characteristics and heat transfer mechanism of 3He - 4He mixture under the milli-Kelvin temperature range. Based on the modified two-fluid model and seepage theory, an energy model combining heat and mass transfer and a concentration diffusion model were introduced. By controlling the seepage rate and limiting the solubility of the mixture, a coupling model of seepage and heat transfer for the 3He - 4He mixture was established. The relationships between osmotic pressure and cool-ing temperature, power and heat load were clarified. Sensitivity analysis of the structural parameters of the mixing chamber reveals the permeation and refrigeration mechanism by the entropy variations in the phase interface of the 3He - 4He mixture under extremely low temperature.

(2) Research on the cryogenic interfacial thermal resistance. Under extremely low temperatures, significant interfacial thermal resistance between the fluid and solid exists. Based on the acoustic mismatch model, and considering the mode of particle vibration and low-frequency vibration of the skeleton, thermal resistance calculation models were established for three types of liquid helium and solid wall interfaces. The influences of the wall material, structural parameters, and flow parameters on the interface thermal resistance were further analyzed, which provides a theoretical basis for the study of enhanced heat transfer at extremely low temperature.

(3) Cryogenic heat transfer characteristics of the porous media. Metal sintered structures are commonly used in milli-Kelvin level temperature heat transfer processes between the liquid 3He and 3He - 4He mixtures, directly affecting refrigeration temperature and cooling capacity. Considering the interface thermal resistance, physical properties of the working fluid, and viscous heat, a numerical model for the heat transfer of cryogenic sintered structures was established based on the non-thermal equilibrium model and the free flow-porous media seepage coupling model. The influences of porosity, sintered particle size, liquid gap structure and volume, thermal properties, and viscous heat on the cryogenic heat transfer and flow were revealed.